Loading ...

Please click anywhere to start.

Welcome to Bosch’s A2L Transition Course!

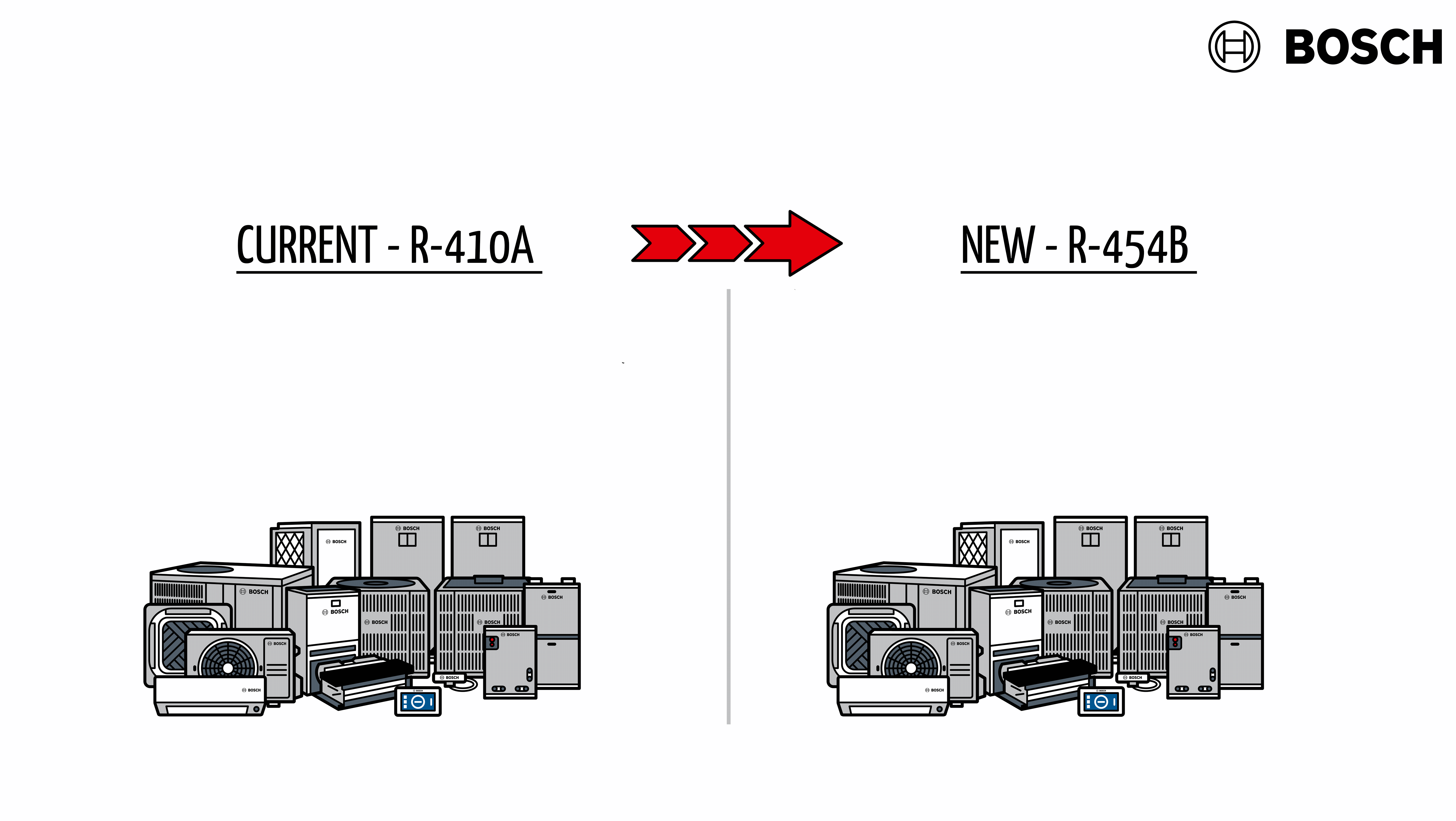

Equipment Changes

Select each point on each product to see what features replacement models will have compared to

current models.

CURRENT - R-410A

NEW - R-454B

Industry best business practices

recommended, but no specific R-410A

refrigerant flammability safety

requirements.

NO R-410A refrigerant leak sensor.

NO compressor operation or blower

change for R-410A refrigerant leak

detection.

R-454B refrigerant flammability

safety requirements required.

R-454B leak sensor provided.

R-454B leak detection by sensor will

disengage compressor and energize

constant blower operation for

refrigerant vapor dilution within space.

Best Practices

Cycle through each image to see best practices that should be done before charging.

you

spin

me

right

round

Safety and Transportation Considerations

Safety protocols for new R-454B and past refrigerants are largely the same with many of the best practices

commonly used today with R-410A still applicable. However, an increased focus on safety is required. Select each

checkbox after reading each item to confirm you understand both safety and transportation considerations.

Safety Considerations

-

R-454B is mildly flammable so it should be handled

appropriately -

Understand the refrigerant’s properties and use,

personal protective equipment(PPE), and equipment

manufacturer installation criteria -

Follow the manufacturer’s recommendations and

refer to the R-454B SDS (safety data sheet) for

specific hazards and mitigation issues -

When brazing a system that has been charged with

an A2L refrigerant NFPA 704 hazard placards must

be placed in visible locations around the jobsite.

The refrigerant tubing should be pressurized with

air to stabilize the inner walls. The system charge

must be vented to the atmosphere before beginning

Transportation Considerations

During transportation of A2L refrigerants:

-

Ensure a dry-powder Class B fire extinguisher is

available on the vehicle -

Review all local, state, and federal regulations

applicable in the jurisdiction of transport -

Do not store refrigerant cylinders near heat or a source

of ignition -

Label all refrigerant cylinders following guidelines in

US 49 CFR part 172.417 -

Secure flammable refrigerant cylinders to prevent

theft, tampering, or movement during transport

Congratulations!

You completed Bosch’s A2L Transition Course!

As a note, Bosch can continue to offer replacement components for R-410A systems after Jan 1, 2025 to facilitate equipment repairs.

A2L Transition

SECTIONS

GWP:

- Global Warming Potential. A rating system to measure GWP. Must be <700 GWP to be compliant

HFC:

- Synthetic refrigerant gases made up of hydrogen, fluorine, and carbon commonly used in air conditioning systems. Short-lived greenhouse gases that impact global warming and can be many times more powerful than carbon dioxide

AIM ACT:

- The AIM ACT mandates a 15-year phasedown of HFCs at a national level, administered by EPA, and aligned with the Kigali schedule

LOWER FLAMMABILITY LIMIT (LFL):

- Lowest amount of a specific refrigerant in air that allows for flammability

A2L:

- A = nontoxic

- 2 = flammable

- L = low burning velocity

R-454B REFRIGERANT:

- Mildly flammable low global warming potential (GWP) hydrofluoroolefin-based zeotropic blend of R-32 and R-1234yf

Well done!

You correctly did it.

Not quite.

There were some issues.

Not quite.

There were some issues.