Electric Water Heaters Troubleshooting

Greentronic 7000 screenings are available for error codes.

GreenTronic 7000 T

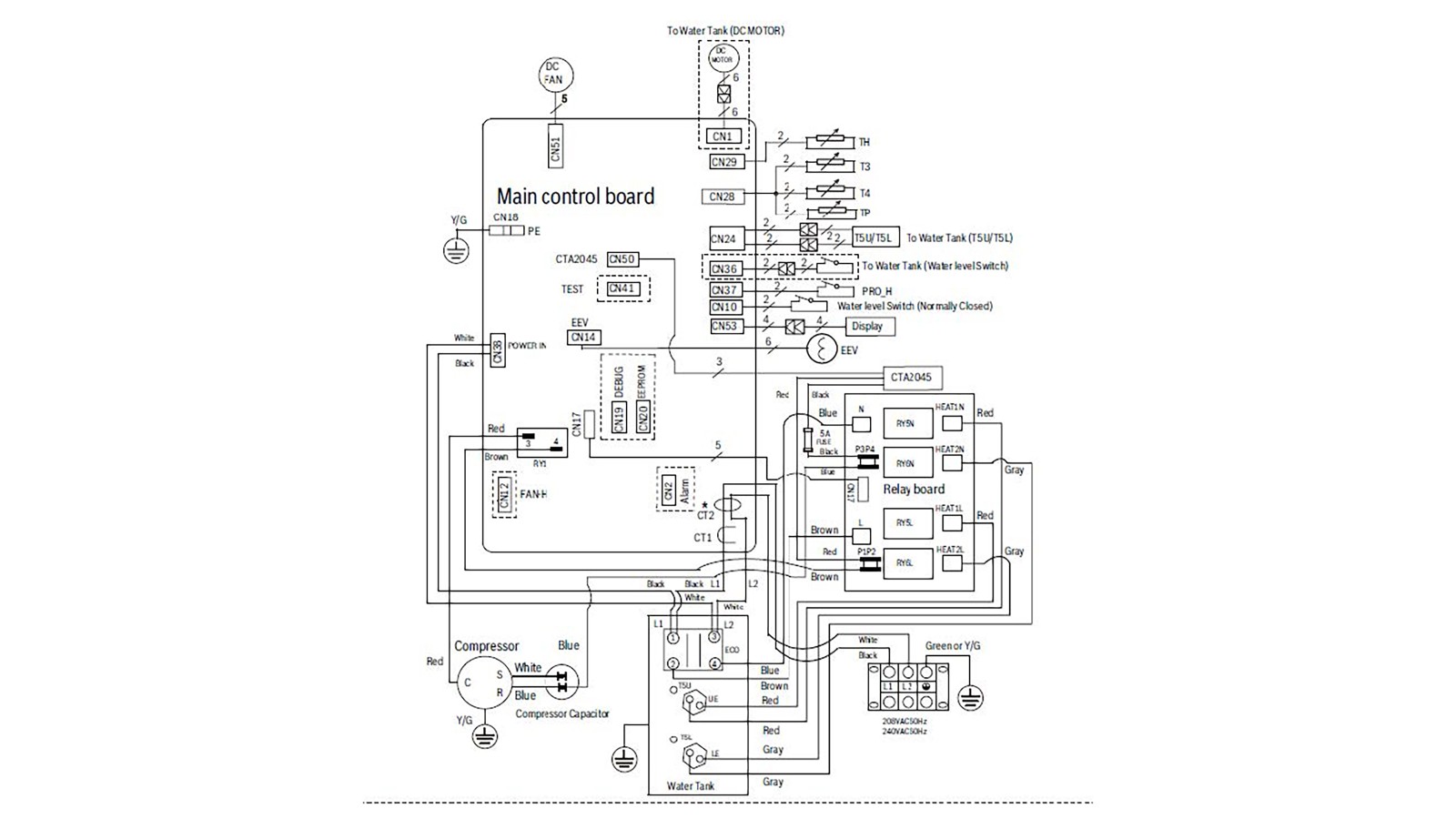

Greentronic 7000 T Wiring Diagram

3 GreenTronic 7000 T - Code EC52

3.1 Tech Support Enhanced Screening

3.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EC52 |

3.1.2 Error Code Information

| Error Code | EC52 |

|---|---|

| Error Code Meaning |

T3 temp sensor not detected |

| Possible Causes |

Broken wire to temp sensor, failed sensor, poor connection to board. |

3.1.3 Tools Needed

Digital Multi-meter

3.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the T3 sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to T3 and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

4 GreenTronic 7000 T - Code EC53

3.1 Tech Support Enhanced Screening

4.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EC53 |

4.1.2 Error Code Information

| Error Code | EC53 |

|---|---|

| Error Code Meaning |

T4 temp sensor not detected |

| Possible Causes |

Broken wire to temp sensor, failed sensor, poor connection to board. |

4.1.3 Tools Needed

Digital Multi-meter

4.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the T4sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to T4 and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

5 GreenTronic 7000 - Code EC54

5.1. Tech Support Enhanced Screening

5.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EC54 |

5.1.2 Error Code Information

| Error Code | EC54 |

|---|---|

| Error Code Meaning |

TP temp sensor not detected |

| Possible Causes |

Broken wire to temp sensor, failed sensor, poor connection to board. |

5.1.3 Tools Needed

Digital Multi-meter

5.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the TP sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to TP and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

6 GreenTronic 7000 - Code EH00

6.1 Tech Support Enhanced Screening

6.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EH00 |

6.1.2 Error Code Information

| Error Code | EH00 |

|---|---|

| Error Code Meaning | Control board error |

| Possible Causes | Bad control board |

6.1.3 Tools Needed

None needed for this code.

6.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be power supply issue. Put the unit back in service and monitor it for further errors.

- If no – If onsite with tools, transfer to the technical support specialists.

7 GreenTronic 7000 - Code EH0b

7.1 Tech Support Enhanced Screening

7.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EH0b |

7.1.2 Error Code Information

| Error Code | EH0b |

|---|---|

| Error Code Meaning |

Display communication failure to board |

| Possible Causes |

Broken wire, failed control board, poor connection to board. |

7.1.3 Tools Needed

Digital Multi-meter (if no tools, no tier 2 transfer)

7.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the display board are tight.

- If no - Go to Step 2

Step 2. Check incoming power and breaker size.

- Have the caller test for VAC across L1 and L2. Make note of the result in ISM.

- Ask the caller what the breaker size is and make note of the answer in ISM.

Results:

- If the caller is on site with tools, transfer them to the technical support specialists.

8 GreenTronic 7000 - Code EH03

8.1 Tech Support Enhanced Screening

8.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EH03 |

8.1.2 Error Code Information

| Error Code | EH03 |

|---|---|

| Error Code Meaning | Fan not detected. |

| Possible Causes |

Broken wire to fan, failed control board, poor connection to board. |

8.1.3 Tools Needed

Digital Multi-meter

8.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

-

- If yes – Could be connection issue. Have the caller confirm the wire connections for the fan are tight.

- If no – Could be open sensor or connection issue. Go to Step 2.

Step 2. Is the fan running?

- Update the information in ISM to indicate if the fan is running or not. Go to step 3.

Step 3. Checking wiring connections

- Check all low voltage wiring for proper connection and transfer the caller to the technical support specialists.

9 GreenTronic 7000 - Code EH5d

9.1 Tech Support Enhanced Screening

9.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EH5d |

9.1.2 Error Code Information

| Error Code | EH5d |

|---|---|

| Error Code Meaning | Heating elements open |

| Possible Causes |

Failed heating elements Bad control board Incorrect wiring |

9.1.3 Tools Needed

Digital Multi-meter (if no tools, no tier 2 transfer)

9.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have them confirm the wire connections to the heating elements are tight. Update ISM and end the call.

- If no - Go to Step 2.

Step 2. Check OHMS on each element

Shut power off to the unit and confirm no power at the L1/L2 of the terminal block.

- Have the caller set their digital multi-meter to ohms.

- Place a probe on each of the ends of the top element.

- Record the ohm reading.

- Place a probe on each of the ends of the bottom element.

- Record the ohm reading.

Results:

- If reading 12.8 OHMS (+/- 10%) go to step 3.

- If reading open or outside of 12.8 ohms (+/- 10%), replace that element. Give part number, update ISM and end the call.

Step 3. Checking wire connections to the elements.

Have the caller confirm that the wire connections to the elements are tight and that the wires are not damaged.

Results:

- Make note of the wire connections in ISM and transfer the caller to the technical support specialists.

10 GreenTronic 7000 - Code EH5H

10.1. Tech Support Enhanced Screening

10.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EH5H |

10.1.2 Error Code Information

| Error Code | EH5H |

|---|---|

| Error Code Meaning |

TH temperature sensor not detected. |

| Possible Causes |

Broken wire to temp sensor, failed sensor, poor connection to board. |

10.1.3 Tools Needed

Digital Multi-meter

10.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the TH sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to TH and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

11 GreenTronic 7000 - Code EH5L

11.1. Tech Support Enhanced Screening

11.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EH5L |

11.1.2 Error Code Information

| Error Code | EH5L (L stands for "lower") |

|---|---|

| Error Code Meaning | T5L temperature sensor not detected. Temp sensor lower element |

| Possible Causes |

Broken wire to temp sensor Failed sensor Poor connection to board |

11.1.3 Tools Needed

Digital Multi-meter

11.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the T5L sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to T5L and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

12 GreenTronic 7000 - Code EH5U

12.1. Tech Support Enhanced Screening

12.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EH5U |

12.1.2 Error Code Information

| Error Code | EH5U (U stands for "upper") |

|---|---|

| Error Code Meaning | T5U temperature sensor not detected. Temp sensor upper element |

| Possible Causes |

Broken wire to temp sensor Failed sensor Poor connection to board |

12.1.3 Tools Needed

Digital Multi-meter

12.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the T5U sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to T5U and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

13 GreenTronic 7000 - Code EHHP

13.1. Tech Support Enhanced Screening

13.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-EHHP |

13.1.2 Error Code Information

| Error Code | EHHP |

|---|---|

| Error Code Meaning | Heat pump system fault 3 times in a row or longer than one hour |

| Possible Causes |

Compressor not heating Compressor current to large Low refrigerant |

13.1.3 Tools Needed

Digital Multi-meter

13.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle?

- YES – Could be connection issue. Recommend that the caller ensure all wire connections are tight, note ISM and end the call.

- NO – Go to step 2.

Step 2. If on site with tools, transfer the call to the technical support specialists.

14 GreenTronic 7000 - Code FC06

14.1. Tech Support Enhanced Screening

14.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-FC06 |

14.1.2 Error Code Information

| Error Code | FC06 |

|---|---|

| Error Code Meaning | Auto shut-off valve not detected |

| Possible Causes |

Bad connection faulty wiring wrong setting |

14.1.3 Tools Needed

Digital Multi-meter

14.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle?

- YES – Could be connection issue. Recommend that the caller ensure all wire connections are tight, note ISM and end the call.

- NO – Go to step 2.

Step 2. Check if auto shut-off valve is installed. The auto shut-off valve is an accessory and not required.

- YES – Check for tight wire connection to auto shut-off valve.

- If they were tight, note ISM and go to step 3.

- If they were loose, the error should go away. Note ISM and end the call.

- NO – Go to step 3.

Step 3. Check auto shut-off valve setting.

- Go into advanced settings on the control by holding the settings button for 3 seconds.

- Use the Up/Down arrows to scroll down to F38.

- Use the "Check" button in the bottom row on the right.

- Change the setting to "0".

- Hit the "Back" button to the left of the "Check" button to save this change and note this in ISM.

- If on site with tools, transfer the caller to the technical support specialists.

15 GreenTronic 7000 - Code PC06

15.1. Tech Support Enhanced Screening

15.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PC06 |

15.1.2 Error Code Information

| Error Code | PC06 |

|---|---|

| Error Code Meaning |

High temperature at TP sensor (TP > 230°F /110°C). Clears when TP < 194°F/90°C: if error repeats, call technician. |

| Possible Causes |

Damage to the refrigerant line. Low refrigerant. Bad wire connection Bad sensor |

15.1.3 Tools Needed

Digital Multi-meter

15.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the TP sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to TP and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

16 GreenTronic 7000 - Code PC30

16.1. Tech Support Enhanced Screening

16.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PC30 |

16.1.2 Error Code Information

| Error Code | PC30 |

|---|---|

| Error Code Meaning |

High refrigerant pressure detected > 435 PSI when compressor on > 350 PSI when compressor off |

| Possible Causes |

Bad high pressure switch Low air flow |

16.1.3 Tools Needed

Digital Multi-meter

16.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be power supply issue. Put the unit back in service and monitor it for further errors.

- If no – If onsite with tools, transfer to the technical support specialists.

17 GreenTronic 7000 - Code PH9b

17.1. Tech Support Enhanced Screening

17.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PH9b |

17.1.2 Error Code Information

| Error Code | PH9b |

|---|---|

| Error Code Meaning | Water temperature exceeds set point by 9°F (5°C) |

| Possible Causes |

Bad wire connection Bad T5U sensor |

17.1.3 Tools Needed

Digital Multi-meter

17.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections for the T5U sensor are tight.

- If no – Go to Step 2.

Step 2. Check the sensor through the display to see the reading

- To check the reading, press the settings button on the control panel.

- Using the Up and Down arrows, scroll down to T5U and record the numbers in the center of the display in ISM.

- Transfer the call to the technical support specialists.

18 GreenTronic 7000 - Code PH15

18.1. Tech Support Enhanced Screening

18.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CCEC54 |

18.1.2 Error Code Information

| Error Code | PH15 |

|---|---|

| Error Code Meaning | Electric leakage detected, water heater cannot run |

| Possible Causes |

Bad circuit Breaker Faulty Wiring |

18.1.3 Tools Needed

Digital Multi-meter

18.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be power supply issue. Put the unit back in service and monitor it for furthererrors.

- If no – Make note of the breaker size and if onsite with tools, transfer to the technical support specialists.

19 GreenTronic 7000 - Code PH20

19.1. Tech Support Enhanced Screening

19.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PH20 |

19.1.2 Error Code Information

| Error Code | CC-PH20 |

|---|---|

| Error Code Meaning | Compressor is not able to heat up refrigerant |

| Possible Causes |

Sensor issue Compressor issue |

19.1.3 Tools Needed

Digital Multi-meter

19.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be power supply issue. Put the unit back in service and monitor it for further errors.

- If no – If onsite with tools, transfer to the technical support specialists.

20 GreenTronic 7000 - Code PH21

20.1. Tech Support Enhanced Screening

20.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PH21 |

20.1.2 Error Code Information

| Error Code | PH21 |

|---|---|

| Error Code Meaning | Compressor working current too large, Water heater will operate by using electric heating elements only. |

| Possible Causes |

Sensor Issue Compressor Issue |

20.1.3 Tools Needed

Digital Multi-meter

20.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be power supply issue. Put the unit back in service and monitor it for further errors.

- If no – If onsite with tools, transfer to the technical support specialists.

21 GreenTronic 7000 - Code PH22

21.1. Tech Support Enhanced Screening

21.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PH22 |

21.1.2 Error Code Information

| Error Code | CC-PH22 |

|---|---|

| Error Code Meaning |

Leak sensor activated. Water heat can operate normally. |

| Possible Causes |

Water leak Refrigerant leak |

21.1.3 Tools Needed

Digital Multi-meter

21.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be power supply issue. Put the unit back in service and monitor it for further errors.

- If no – If onsite with tools, transfer to the technical support specialists.

22 GreenTronic 7000 - Code PH24

22.1. Tech Support Enhanced Screening

22.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PH24 |

22.1.2 Error Code Information

| Error Code | PH24 |

|---|---|

| Error Code Meaning | T5L sensor is < 39°F/4°C and T4 sensor < 45°F / 9°C: Frost Protection active |

| Possible Causes |

Sensor issue Wiring issue |

22.1.3 Tools Needed

Digital Multi-meter

22.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be power supply issue. Put the unit back in service and monitor it for further errors.

- If no – If onsite with tools, transfer to the technical support specialists.

23 GreenTronic 7000 - Code PH91

23.1. Tech Support Enhanced Screening

23.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PH91 |

23.1.2 Error Code Information

| Error Code | PH91 |

|---|---|

| Error Code Meaning | Evaporator temperature too low |

| Possible Causes |

Bad wire connection Bad temp sensor Ambient air is to cold (< 39°F) |

23.1.3 Tools Needed

Digital Multi-meter

23.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections are tight.

- If no – Could be open sensor or connection issue. Go to Step 2.

Step 2. Check ambient air temp

Is the air around the unit below 39°F? YES/NO

- YES – likely too cold for machine. Have the caller increase the temperature of the air around the unit. Note this in the ISM record and end the call.

- NO – If the caller is a technician on site with tools, transfer them to the technical support specialists.

24 GreenTronic 7000 - Code PHL1

24.1. Tech Support Enhanced Screening

24.1.1 ISM Notes

|

General Reason |

CC-7000T |

|

Specific Reason |

CC-PHL1 |

24.1.2 Error Code Information

| Error Code | PHL1 |

|---|---|

| Error Code Meaning |

Water detected in condensate tray. Water heater will operate by using electric heating elements only. |

| Possible Causes |

Condensate drain is blocked Bad float switch. |

24.1.3 Tools Needed

Digital Multi-meter

24.1.4 Enhanced Screening Questions (What to do?)

Step 1. Power Cycle

Does the unit reset after power cycle: YES/NO

Results:

- If yes – Could be connection issue. Have the caller confirm the wire connections are tight.

- If no – Could be open sensor or connection issue. Go to Step 2.

Step 2. Check the condensate drain

Is the condensate drain clean? YES/NO

- YES – transfer the caller to the technical support specialists.

- NO – need to clean drain